Wood is an amazingly versatile building material. Its tensile strength, ease of fabrication, insulation properties, and aesthetic appeal are a few remarkable qualities that make it one of the favorite choices in exteriors and interiors. It is mainly grouped into the engineered wood and solid wood, which is a common term that distinguishes wood in many factors; solid wood will remain the main focus throughout the following article. A single piece of kiln-dried timber from a tree that mill into a plank is known as Solid wood, which has been classified into two categories: Softwood and Hardwood.

Hardwood comes from deciduous trees, which lose their leaves annually. Hardwood trees are slow-growing trees that take up to hundred years to mature fully. Therefore there grain structure appears to be dense and closer. Dimensional lumber from hardwood is always expensive compare with softwood. Hardwood is a material of real beauty with countless combinations of colors and specifications.

Softwood, on the other hand, obtains from coniferous trees, which usually remain evergreen. Softwoods, compare with Hardwood, are flexible, less dense, and light in weight; therefore, they cost cheaper. Softwoods are most commonly used in making sheet goods such as fiberboard and plywood. From furniture to structural applications in interior and exterior projects, softwood gives a remarkable aesthetic appeal.

When no longer a tree, distinguishing a wood on its appearance is difficult, especially after staining or polishing. Besides, wood changes its color over time, and many species share similar grain patterns. Therefore, the absolute best way to recognize wood is to know all the different characteristics of its resistance properties, color, and hardness.

SOFTWOODS (A type of solid wood use in building materials)

Cedar or Deodhar softwood

Durable, attractive, and versatile, Cedar is well-known for its aromatic essence. It typically thrives in damp climates. Therefore, it does not swell, warp, shrink or decay in extreme weather conditions. The light and dark color combinations with slight pink and red hues make it ideal for construction and making furniture. Also, the straight grain pattern with an occasional swirl and knotty feature adds beauty to Cedarwood. The presence of oil makes Cedar a flammable wood. Yet, great workability and durability compel Cedar in various indoor and outdoor applications.

Fir

It is the most stronger and harder than other softwoods yet, less prone to warping or twisting. Although Fir lumber may shrink and expand, but returns to the same shape in a typical climate. The grain patterns usually appear in dull yellow color with long straight lines. Therefore, it lacks character and beauty. But the moderate natural luster can enhance with stains, paints, or finishes. However, fir lumber provides good stability when used for exterior applications such as decking and outdoor furniture.

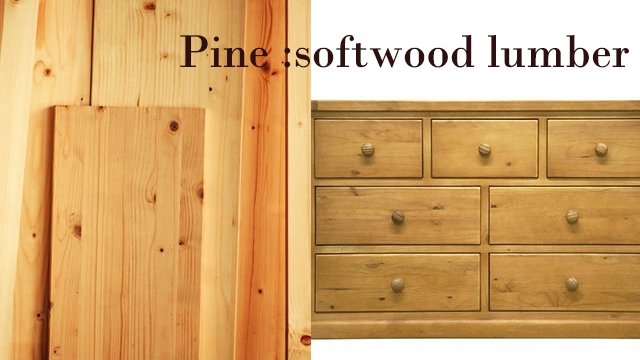

Pinewood

The broad grain lines make pine weaker and softer than Fir, but the aesthetic point of view holds much more character than Fir. Colors ranging from brown to amber and pale white with knotty features give pine a beauty, therefore, a preferable choice. Also, unlike Fir, pine is not resistant to decay and completely loses its original shape if it swells or wraps in extreme weather conditions. Hence only pressure-treated Pine can last long in outdoor applications.

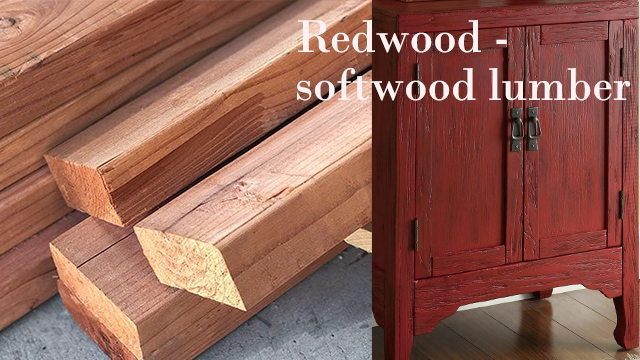

Redwood

A recyclable and sustainable Redwood has long been in the building material because of its legendry durability and magnificent beauty. It has come from the forest where trees grow slowly; hence, it is more durable and long-lasting than all other softwood species. Redwood lumber appears in a rich grain pattern and a reddish warm tone. It is naturally resistant to decay and moisture therefore suitable for outdoor applications.

HARDWOODS (A type of solid wood use in building materials)

Ash solidwood building material

The light brown and creamy white tone in a straight grain pattern gives Ashwood a simple and uniform look. It is medium in density and hardness; therefore easy to work with tools, but the porous grain surface has to fill before applying finishes. Due to medium density, it is not a good choice in exterior applications as it may attack by insects and fungus or bend if contact with humid and damp climate. However, Ashwood is less expensive compare with other hardwood with similar properties.

Birch solid wood building material

Commercially popular and reasonably priced, Birch hardwood comes in more than 50 species around the globe. Sapwood, the outermost portion of the Birch, appears in creamy white to yellow color, and the heartwood appears in golden brown. It has a fine and tight pores structure compared with Maple, therefore stains into beautiful, uniform finishes. Without proper pressure applications during the drying process, Birch lumber loses about 15% of its volume and may curl. Birchwood is not resistant to decay and fungus and not even a suitable choice for exterior applications.

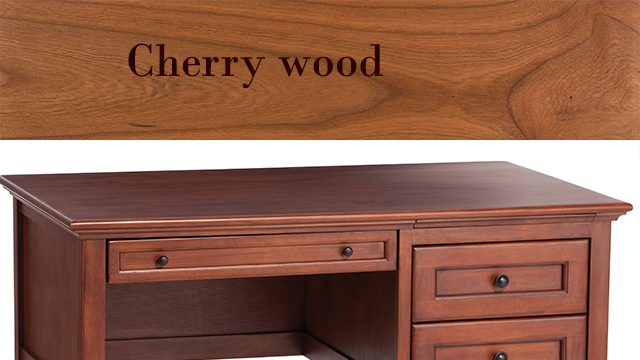

Cherry solid wood building material

Notable for its natural luster and smooth texture, Cherry hardwood appears in reddish-brown with a uniform, straight grain pattern. A freshly cut cherry comes in a light pale color that changes from light pink to darker brown over the aging process. However, the aging process can accelerate by exposing the wood to natural light as much as possible. The medium dense grains give cherry wood a good bending property. Therefore it is most suitable in curve and molds applications. In addition, the heartwood from the cherry tree is resistant to rot and decay but not with water and moisture damage.

Mahogany solid wood building material

Extremely durable and water-resistant, Mahogany wood can withstand bad weather conditions as well. Therefore, it is a perfect choice for outdoor applications. Despite being a hardwood, it is ideal for working with hand tools, often found in carving applications. Furthermore, Polish gives Mahogany a rich appearance and enhances its life span.

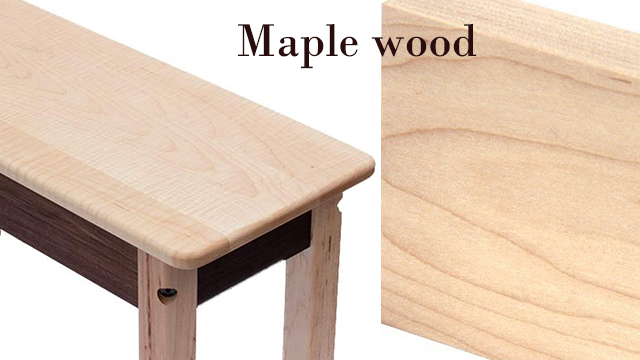

Maple solid wood building material

An undeniable beauty of Maple wood that ranges between warm to neutral color tones can complement any interior color scheme. Moreover, the subtle, smooth, and clean grain pattern of Maple adds minimalism to interiors. Maple is, however, can expand or contract, warp or split in humid climates. Darker hues can achieve through staining and dying, but the stain doesn’t absorb well due to the tight grain pattern and leaves uneven patches.

Oak solid wood building material

Every species of Oak hold a strong, hard, and dense grain structure and therefore is resistant to water, insect, and fungal infestation. Oak furniture looks great in any interior composition as it stains and polishes well as per desired finishes. However, care to be taken because wet and cold weather can react to oil finishes. The strength and stability of Oak are great in high wear and tear applications; hence it is used in decking, flooring, joineries, paneling, and heavy furniture.

Teak (Saag) solidwood building material

The charming Teak is a solid wood used in building material for its high-end royal appearance. The polishes, paintings, and varnishes give Teak a rich and classy finish. Teak’s close and tight grains make it durable and resistant to water and termite, therefore suitable for exterior applications. In addition, the elasticity and solid fiber of Teakwood facilitate greatly carving and molding in furniture production.

Walnut solidwood building material

Appears to upscale the luxurious aesthetic, Walnut is a beauty with elegant hardwood, which is the preferable choice in contemporary minimal interiors. Blackish to light brown color tones with the hint of red and purple in shimmer wash give walnut a lively surface. Moreover, irregular, cloudy, or stripped grain patterns are much appreciated without any surface treatment or clear transparent varnishes. Walnut, too is from the high price hardwood categories yet not resistant to moisture and weather conditions; hence not recommended in outdoor applications.

Salwood

The highly durable and strong Salwood is a solid wood use in building material for making window sills, door frames, and beam structures. However, it can easily crack if exposed to sunlight and even shrink and swell in extreme weather conditions. The finished surface of the Sal wood does not hold aesthetic character; therefore, it tucks well behind in upholstered furniture framing. The coarse grain structure of the Sal wood is difficult to polish but can paint or oil. The seasoning process makes the wood resistant to water, fungi, termites, and white ants. It is 50% heavier and tougher than Teakwood; hence difficult to saw and mold into any shape.

Drawback

Although the beauty and durability of Solid wood are remarkable, there are many drawbacks because of which Engineered wood is gaining popularity and demand in the market. In addition, solid wood is an expensive group of wood compares to any engineered board. Moreover, the resistance capacity of various factors depends on the quality of surface treatment and extremity of climatic conditions.